Common Well Logging Issues and How to Overcome Them

Introduction to Well Logging in Oil and Gas

Well logging is a crucial technique used in the oil and gas industry to gather subsurface data about a well. This data helps engineers and geologists understand the composition, permeability, and potential production capacity of the rock formations encountered during drilling. Logging involves the measurement of various properties such as resistivity, porosity, and density at different depths within the well. The data collected assists in making informed decisions regarding drilling, reservoir management, and exploration. However, like any technology, well logging is prone to challenges that can impact the accuracy and quality of the data. In this article, we will explore the common issues faced during well logging and provide solutions to overcome them.

Common Well Logging Issues

Well logging, while a critical process, is fraught with potential challenges that can compromise data integrity and lead to inaccurate reservoir characterization. These issues can arise from a variety of factors, including tool malfunctions, adverse borehole conditions, data acquisition and interpretation difficulties, and fluid-related problems. Understanding these common pitfalls is the first step in mitigating their impact.

Tool Malfunction or Failure

Tool malfunction or failure is one of the most frequent issues encountered during well logging. Logging tools operate under demanding downhole conditions, including high pressures, extreme temperatures, and corrosive environments, all of which can cause mechanical failures or lead to inaccurate readings. If tools malfunction, valuable data may be lost, and logging activities could face delays, leading to expensive downtime.

To reduce the likelihood of tool malfunctions, it is essential to conduct regular maintenance and pre-deployment checks. Before each use, tools should be thoroughly inspected and calibrated to ensure they are in proper working order. Moreover, having backup tools on hand can help minimize disruptions caused by tool failure, allowing logging operations to proceed without interruptions.

Poor Data Quality

Poor data quality is another significant issue during well logging. Factors such as electrical noise, improperly calibrated sensors, or tool drift can cause inaccurate or distorted measurements. When data quality is compromised, it becomes difficult to make informed decisions about the reservoir, leading to potential operational setbacks and increased costs.

To ensure high-quality data, it’s essential to calibrate logging tools before and after every use. Additionally, noise-canceling techniques and filtering methods should be employed to eliminate signal interference. Cross-checking results from multiple tools or data collection methods can also help verify data quality and improve overall accuracy.

Borehole Instability

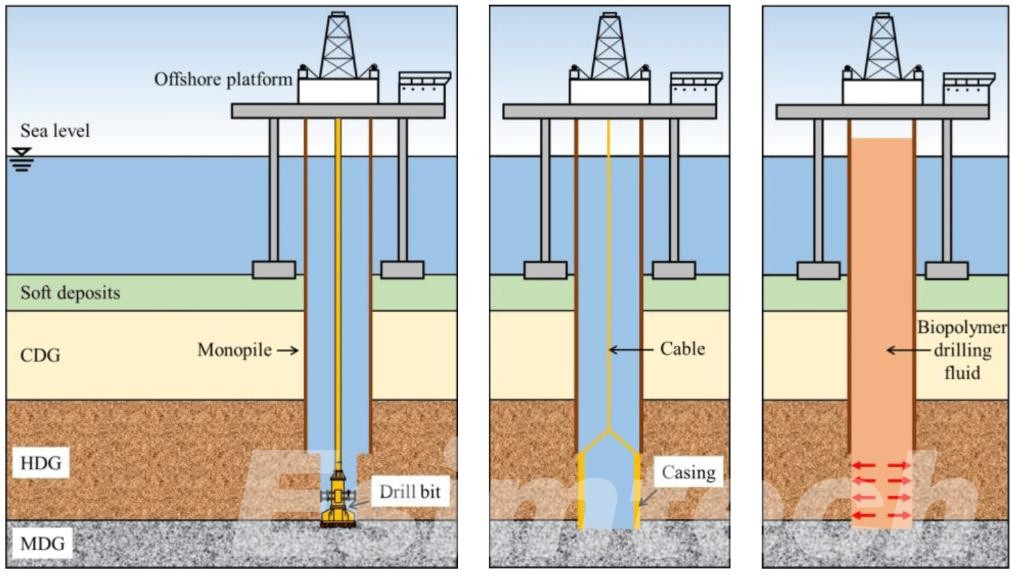

Borehole instability happens when the wellbore deforms or collapses, potentially hindering proper tool deployment and damaging logging equipment. This instability can also lead to inaccurate data, particularly in formations with loose or poorly consolidated rock. Such issues create significant challenges in maintaining a continuous and reliable log of subsurface conditions.

To address borehole instability, operators can employ stabilizing fluids, use proper casing methods, or deploy inflatable tools that offer additional support to the wellbore. Designing wellbores with consideration for potential instability can also lower the chances of this problem occurring. Before logging, evaluating the formation’s integrity and choosing tools suited for unstable conditions can ensure the wellbore remains stable during operations.

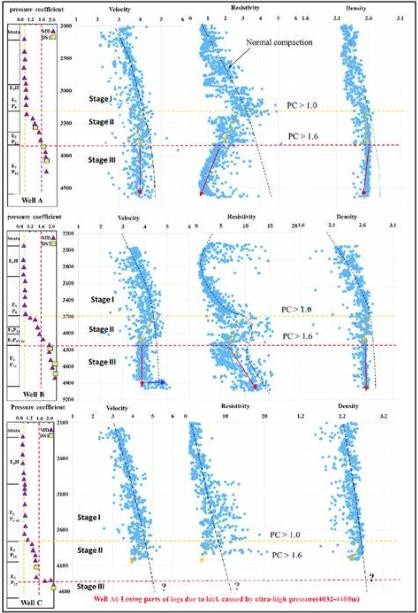

Depth Discrepancies

Depth discrepancies occur when there is a mismatch between the actual depth of the tool in the well and the recorded depth on the log. This issue can arise due to wireline errors, tool stretching, or miscalibration of depth measurement devices. Depth discrepancies can lead to inaccurate data interpretation and poor decision-making during the exploration and drilling phases.

To address depth discrepancies, it’s important to ensure that depth-measuring tools are calibrated properly before use. Regular real-time monitoring of the tool’s position during the logging process is essential for detecting any discrepancies quickly. In cases where depth misalignments occur, applying depth correction algorithms or using tools with built-in depth correction features can help realign data accurately. Additionally, validating depth information with other downhole measurements can help confirm the correct data is being used.

Best Practices to Overcome Well Logging Issues

To overcome common well logging issues and ensure smooth operations, several best practices should be followed:

| Best Practice | Description | Benefits |

| Regular Maintenance & Calibration | Perform routine checks, maintenance, and recalibration of logging tools to ensure proper functionality. | Ensures tools operate optimally in extreme conditions, preventing malfunctions and downtime. |

| Proper Tool Selection | Choose logging tools based on the specific environmental conditions of the well. | Reduces tool failure rates and improves data accuracy by using tools suited to well-specific challenges. |

| Data Verification | Cross-check data from various logging methods and tools for consistency. | Enhances reliability and accuracy of collected data, reducing the likelihood of errors. |

| Real-Time Monitoring | Implement systems for real-time tracking of logging tool performance and data quality. | Allows immediate detection of issues, enabling quick corrective actions to avoid data loss or errors. |

| Advanced Software Utilization | Use advanced software for enhanced data interpretation and anomaly detection. | Improves the quality of data analysis, reducing human error and optimizing decision-making processes. |

By following these best practices, oil and gas operators can effectively address common well logging issues, improve the quality of their data, and streamline operations for better reservoir management.

Emerging Technologies and Innovations in Well Logging

New technological advancements are transforming well logging practices by offering innovative solutions to familiar challenges, boosting data accuracy, and increasing operational efficiency.

A major breakthrough in the field is well logging simulation. With this technology, engineers can create virtual models of logging operations, enabling them to anticipate tool behavior, wellbore conditions, and possible obstacles ahead of the actual process. Through simulation software, operators can explore different logging scenarios, detect potential problems, and refine their choices in tool selection and deployment. This ultimately enhances efficiency, lowers costs, and increases the likelihood of successful outcomes.

In addition to simulation, real-time data transmission has greatly enhanced logging operations. Wireless sensors and advanced telemetry systems allow data to be transmitted from the wellbore to the surface instantly, enabling real-time analysis and decision-making. This innovation has led to faster response times and more accurate adjustments during the logging process.

Other significant advancements involve utilizing downhole imaging technologies to obtain detailed visual representations of the wellbore, as well as leveraging artificial intelligence (AI) for predictive analytics. By processing vast amounts of data, AI algorithms can detect patterns and generate insights that enhance decision-making while reducing human errors. These innovations, which include enhanced data processing and sophisticated software, are optimizing well logging operations, mitigating risks, and enabling operators to achieve more precise and dependable outcomes.

Learn More about Well Logging Practices

Well logging is a fundamental process in the oil and gas industry, providing essential data for reservoir evaluation and drilling decisions. Understanding the common challenges and implementing best practices can significantly improve the accuracy and efficiency of logging operations.

For those looking to enhance their well logging expertise, simulation technology offers an effective way to gain hands-on experience in a controlled environment. Esimtech, a leading provider of oil and gas simulation solutions, offers advanced well logging simulators designed to train professionals in realistic scenarios. These simulators help operators develop practical skills, troubleshoot logging challenges, and refine their decision-making abilities without the risks associated with real-world operations.

To learn more about Esimtech’s well logging simulators and how they can enhance your training programs, visit our website or contact our team for detailed insights.