Best Practices for Managed Pressure Drilling Training and Operator Certification

Managed Pressure Drilling (MPD) is an innovative drilling technique that has transformed the oil and gas industry by offering safer and more cost-efficient operations in challenging environments. However, MPD’s success relies heavily on the skills and expertise of those involved with it; thus this article delves into its importance, training requirements, certification practices as well as best practices for operator certification.

What is Managed Pressure Drilling

Managed Pressure Drilling (MPD) is an advanced drilling technique designed to precisely control the pressure within the wellbore during drilling operations. Unlike traditional drilling methods, which rely on static mud weight to manage pressure, MPD uses a combination of specialized equipment and dynamic processes to maintain optimal pressure conditions. This approach minimizes the risks of formation damage, kicks, and blowouts, making it ideal for challenging environments such as high-pressure, high-temperature (HPHT) wells, deepwater operations, and depleted reservoirs.

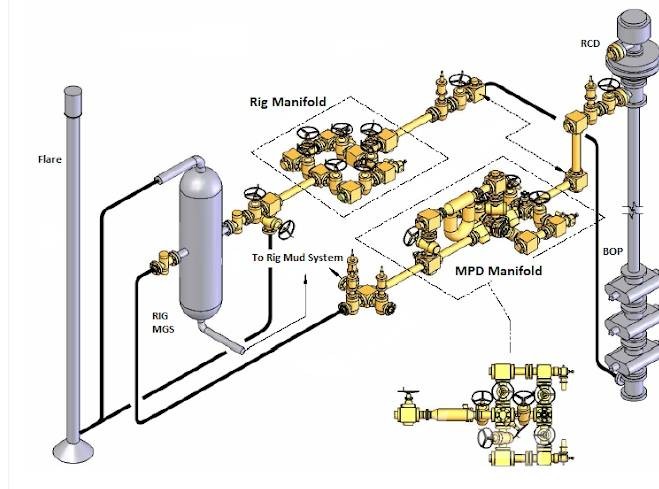

MPD employs tools like rotating control devices (RCDs), choke manifolds, and real-time pressure monitoring systems to adjust pressure dynamically. By maintaining a narrow pressure window, MPD enhances drilling efficiency, reduces non-productive time (NPT), and improves overall safety. It is particularly valuable in complex scenarios where conventional drilling methods fall short, such as narrow margin drilling or geothermal exploration. As the oil and gas industry continues to push into more challenging frontiers, MPD has become a critical technology for achieving operational success while minimizing risks.

Importance of Managed Pressure Drilling Training and Certification

Managed Pressure Drilling (MPD) is an intricacie technique requiring extensive experience and expertise for successful execution. As more complex drilling operations turn towards MPD as part of their operations, training and certification become even more necessary.

- Safety must always come first in any drilling operation, and MPD involves managing precise pressure profiles in high-risk environments like high-pressure, high-temperature (HPHT) wells or deepwater drilling. Proper training ensures operators can recognize potential hazards, respond quickly to emergencies and prevent incidents like blowouts or control issues that might otherwise arise.

- MPD offers many other advantages as well, including efficiency. Highly trained operators can optimize drilling processes to decrease non-productive time (NPT) and limit costly errors. Certification validates an operator’s ability to use advanced equipment and techniques, leading to smoother operations and better outcomes.

- Thirdly, meeting industry standards and regulations is of utmost importance. Many regulatory bodies and companies require MPD operators to hold certifications to demonstrate adherence to safety and operational guidelines and show professionalism and accountability.

- Training and certification help operators build confidence and competence, equipping them to make informed decisions under pressure. In an industry where mistakes can have severe repercussions, investing in proper training is not simply best practice–it is essential to success.

Key Components of Effective Managed Pressure Drilling Training Programs

An effective Managed Pressure Drilling (MPD) training program is key for equipping operators with the skills and knowledge to safely navigate complex drilling situations efficiently and safely. Here are its essential components:

- Comprehensive Theoretical Knowledge

Establishing a firm foundation in MPD principles is of utmost importance. Training should focus on its fundamentals – its purpose, techniques and applications; operators should understand equipment such as choke manifolds, rotating control devices (RCDs), pressure monitoring systems; as well as well control strategies, pressure management practices and risk assessments that prepare trainees for real world situations.

- Real-World Case Studies

Learning from past successes and failures is invaluable, which is why training programs should include real MPD projects with case studies of their challenges, solutions implemented, lessons learned, and success rates as an invaluable way for trainees to develop problem-solving abilities while applying theoretical knowledge practically.

- Engaging in Hands-On Training

MPD Training Simulator: Using advanced simulators to replicate real-world drilling scenarios, allowing trainees to practice pressure control, kick detection, and emergency response in a risk-free environment.

Equipment Operation and Maintenance: Gaining practical experience in operating and maintaining MPD equipment, including troubleshooting common issues.

Emergency Response Drills: Practicing critical procedures, such as well shut-in and blowout prevention, to ensure preparedness for high-pressure situations.

- Safety and Regulatory Compliance

Safety in MPD operations is of utmost importance. Therefore, training must focus on industry safety standards, emergency protocols, and regulatory requirements for well control emergencies. Trainees should learn how to conduct risk analyses, implement safety measures, and respond accordingly in the event of incidents such as well control emergencies.

- Continuous Learning and Skill Development

The oil and gas industry is in constant evolution, so MPD training must adapt accordingly. Effective programs provide access to relevant resources like webinars, workshops and industry publications as well as refresher courses and advanced modules so operators can stay abreast of emerging technologies and best practices.

MPD training programs combine these components to produce operators who are skilled, confident, and safety conscious – ready to face the rigors of modern drilling operations.

Certification Requirements and Standards

To become a certified Managed Pressure Drilling (MPD) operator, individuals must meet specific requirements and adhere to industry standards. Below is a detailed breakdown of the certification process:

| Requirement | Description | Examples/Standards |

| Knowledge Assessment | Comprehensive evaluation of theoretical knowledge on MPD principles, pressure management, and safety protocols. | IADC WellSharp, API Q2 |

| Practical Skills Evaluation | Hands-on performance tests to demonstrate proficiency in handling MPD equipment and responding to well control scenarios. | MPD Simulator Training, Onsite Drilling Exercises |

| Experience Verification | Documented field experience under the supervision of certified professionals. | Work logs, supervisor endorsements |

| Continuing Education | Ongoing training to stay current with new technologies, regulations, and industry best practices. | Periodic refresher courses, seminars |

| Compliance with Safety Standards | Adherence to safety protocols and emergency response procedures to ensure well integrity and prevent incidents. | OSHA Guidelines, HSE Compliance Checks |

Remember:

- Ensure your training provider is recognized by industry bodies like the International Association of Drilling Contractors (IADC) or the International Well Control Forum (IWCF).

- Focus on both theoretical knowledge and practical skills to excel in certification exams.

- Regularly renew your certification and participate in continuous learning to keep up with evolving MPD technologies and standards.

By meeting these requirements and following industry standards, MPD operators can demonstrate their expertise and commitment to safe, efficient drilling operations.

Best Practices for Managed Pressure Drilling Operator Certification

Attaining Managed Pressure Drilling operator certification requires an organized and systematic approach that prioritizes both technical competence and safety awareness. A key best practice for MPD certification success is implementing training programs aligned with industry standards, such as those from IADC or API. Such programs should cover both theoretical knowledge as well as practical skills required for operating MPD equipment and managing wellbore pressure effectively.

Competency-based assessments play an integral part of the certification process. Evaluations should test not only an operator’s understanding of MPD principles but also his/her response time to real world drilling scenarios and well control situations. Hands-on experience also plays an essential part, providing operators a chance to apply their knowledge safely through simulator training or supervised field practice.

Recertification is another essential part of maintaining operator proficiency. As technology and industry practices advance, regular assessments and continuing education programs help operators keep abreast of new MPD techniques and safety protocols. Furthermore, emphasizing safety during certification creates a culture of accountability and preparedness, decreasing well control incidents while increasing overall drilling performance.

Final Thoughts

Managed Pressure Drilling is an integral component of modern drilling operations, but its success relies heavily on trained and certified operators. By investing in comprehensive training programs and adhering to best practices for certification, operators can increase safety, efficiency, and compliance during MPD operations.

As the industry evolves, ongoing education and skill development will remain essential to staying at the top of Managed Pressure Drilling (MPD). From beginner operators to veteran MPD operators, prioritizing training and certification is crucial in unlocking its full potential.