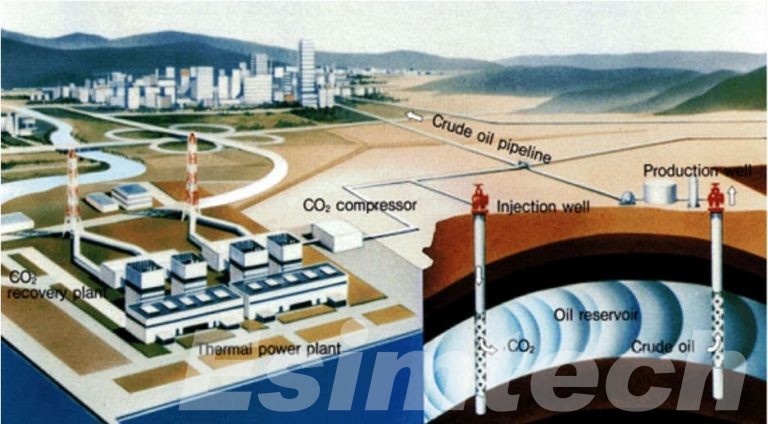

Enhanced Oil Recovery in Unconventional Reservoirs

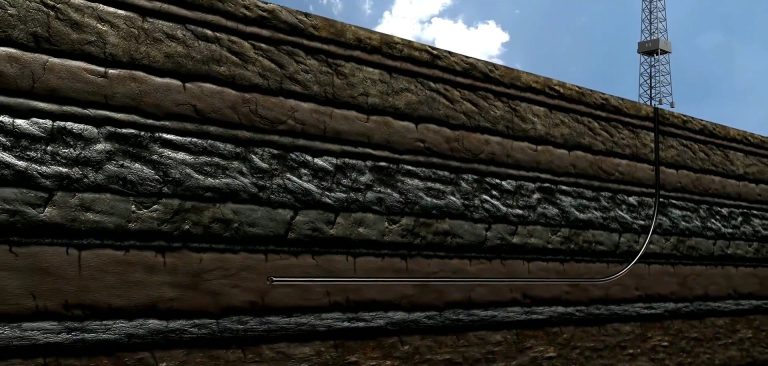

Unconventional reservoirs present unique challenges due to their low permeability, heterogeneity, and complex geomechanics. Traditional primary and secondary recovery methods often yield poor results in these environments, prompting the development and application of Enhanced Oil Recovery (EOR) techniques tailored to the specific conditions of unconventional plays. Understanding Unconventional Reservoirs Unconventional reservoirs are hydrocarbon-bearing formations that cannot produce oil…