Application of Multistage Fracturing in Unconventional Resource Development

The increasing global energy demand, coupled with the depletion of conventional oil and gas reserves, has propelled the exploration and extraction of unconventional resources. Among the most significant technological advancements facilitating this transition is multistage fracturing, a method that enhances hydrocarbon recovery from tight formations. This article delves into the background of multistage fracturing, its advantages in oil and gas extraction, and its diverse applications across various unconventional resources.

Background on Multistage Fracturing

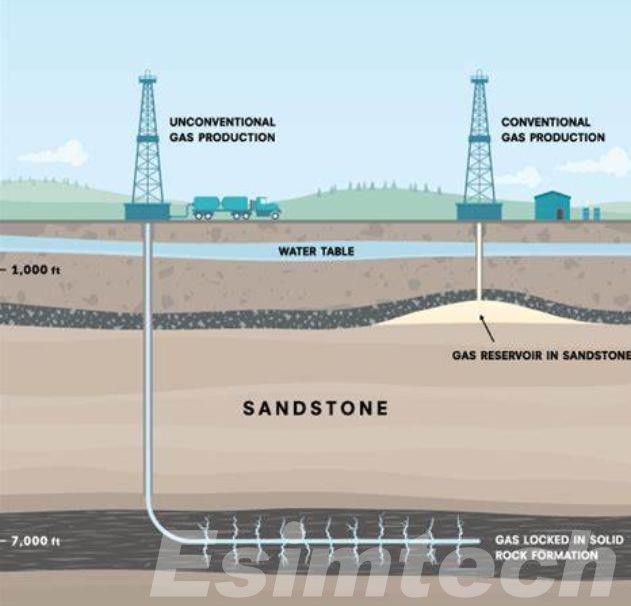

Multistage fracturing, or hydraulic fracturing in multiple stages, is a technique used to maximize the production of oil and gas from unconventional reservoirs, such as shale, tight oil, and tight gas formations. The process is centered around dividing a wellbore into sections (stages) and then fracturing each section individually to create pathways for hydrocarbons to flow. Over time, this method has advanced, becoming a key component in the extraction of unconventional resources.

Key Steps in Multistage Fracturing

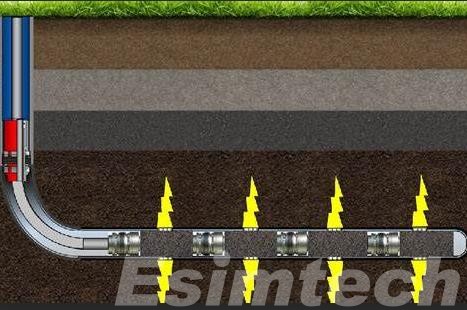

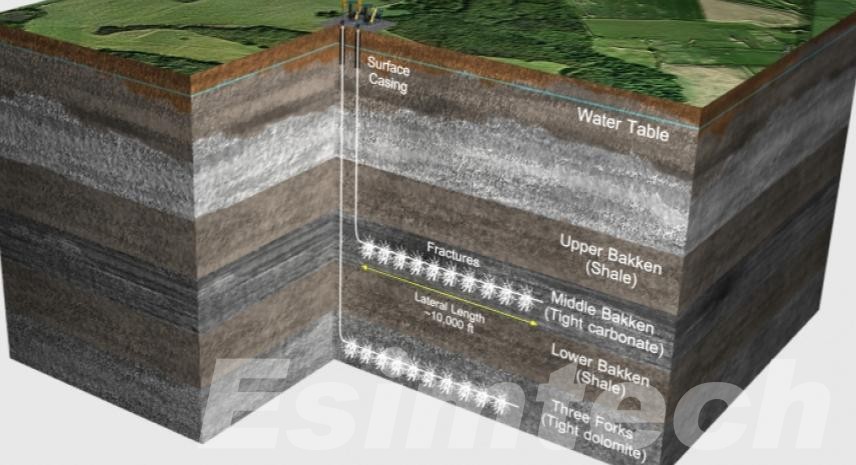

- Horizontal Well Drilling: The process starts by drilling a horizontal well through the target formation, increasing the contact area with the reservoir rock.

- Segmenting the Wellbore: The wellbore is divided into stages using techniques like sliding sleeves or the plug-and-perf method. This segmentation allows operators to target specific sections of the well.

- Hydraulic Fracturing: High-pressure fluids are injected into each stage, creating fractures in the surrounding rock. This increases the permeability of the rock, allowing oil and gas to flow more easily.

- Repeated Stimulation: The process is repeated across multiple stages, creating a network of fractures throughout the reservoir. This ensures maximum resource extraction from the entire length of the well.

- Precision Engineering and Monitoring: Modern multistage fracturing uses real-time data and advanced engineering to optimize the placement and execution of fractures, ensuring efficient and safe operations.

Advantages of Multistage Fracturing Used in Oil and gas

The application of multistage fracturing in oil and gas development offers several advantages that significantly enhance the efficiency and profitability of unconventional resource extraction:

- Improved Reservoir Access

Multistage fracturing enables operators to access extensive portions of a reservoir by creating several fractures along the horizontal wellbore. This approach is especially important in unconventional formations such as shale, where natural permeability is very low. By inducing fractures at different points along the wellbore, the technique enhances the reservoir’s connectivity, allowing oil and gas to flow more easily. As a result, it significantly improves the extraction of trapped hydrocarbons that would otherwise be unrecoverable with traditional vertical drilling or single-stage fracturing techniques.

- Maximized Production and Recovery

One of the key benefits of multistage fracturing is the substantial increase in both initial production rates and long-term recovery. Multiple fractures increase the surface area through which hydrocarbons can flow into the wellbore, leading to higher initial production volumes. Over the life of the well, these fractures also improve overall recovery rates, as they can access hydrocarbons from various layers of the reservoir, depleting the formation more effectively than a single fracture would. This leads to a better return on investment, as more hydrocarbons are produced from each well.

- Economic Efficiency in Unconventional Plays

While multistage fracturing requires higher initial investments due to its complexity, it offers substantial long-term economic advantages. By enabling the stimulation of multiple zones within a single well, it reduces the need for drilling additional wells, thereby cutting overall capital expenditures on drilling and surface infrastructure. The boost in production rates also allows operators to achieve quicker payback periods. In resource-intensive areas like shale plays, where profit margins are often narrow, the combination of increased output and lower drilling costs makes multistage fracturing a financially attractive solution.

- Minimizing Environmental Impact

Multistage fracturing allows operators to extract hydrocarbons more efficiently from a single wellbore, reducing the need for multiple drilling locations. By tapping into a larger portion of the reservoir with fewer wells, this technique decreases surface disruptions, minimizes habitat disturbance, and lowers the overall environmental footprint. In addition, improvements in water recycling and fluid management further address environmental concerns commonly linked to hydraulic fracturing, contributing to a more sustainable approach.

These advantages highlight why multistage fracturing has become a cornerstone of modern oil and gas development, especially in the extraction of unconventional resources.

Multistage Fracturing Application in Different Unconventional Resources

Multistage fracturing has emerged as a crucial technology in the extraction of various unconventional resources. Here are four key applications where this method significantly enhances production capabilities:

Shale Gas Production

Shale gas production is one of the most important applications of multistage fracturing, as it allows operators to unlock vast amounts of natural gas from tight, low-permeability shale formations.

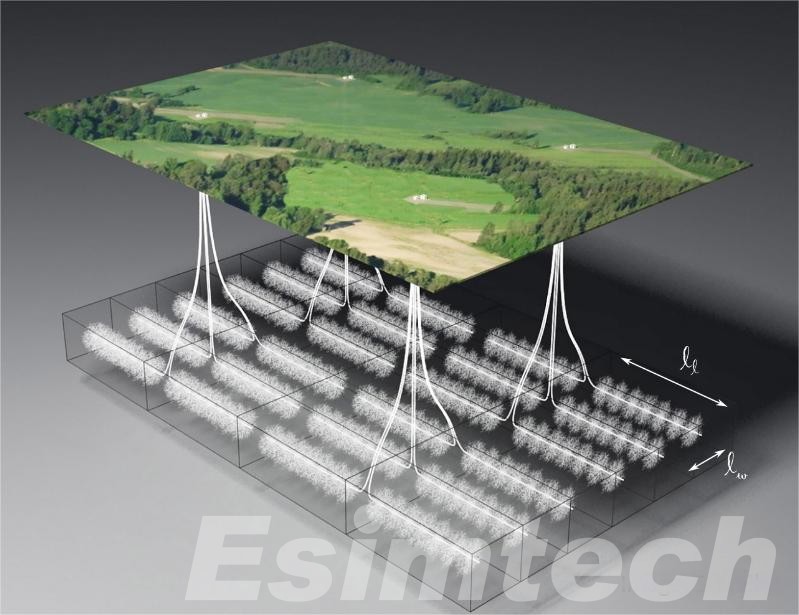

- Increased surface area: By creating multiple fractures along the horizontal wellbore, multistage fracturing dramatically increases the surface area of the rock in contact with the well. This enhanced exposure enables natural gas to flow more easily from the rock to the wellbore.

- Higher production rates: The technique significantly boosts production rates. Some shale wells, such as those in the Marcellus and Barnett formations, can produce millions of cubic feet of gas per day due to the extensive fracture networks created.

- Targeting multiple zones: Multistage fracturing enables operators to target different layers or zones within the same wellbore. This means that more sections of the gas-bearing shale can be tapped simultaneously, maximizing resource recovery and optimizing the overall productivity of the well.

- Economic benefits: By significantly increasing the volume of gas extracted from each well, multistage fracturing improves the economics of shale gas production. It lowers the cost per unit of gas produced, making shale gas extraction not only technically feasible but also financially attractive.

Tight Oil Recovery

Tight oil recovery relies heavily on multistage fracturing to produce oil from reservoirs with low permeability, where natural flow is insufficient.

- Extensive fracture networks: The creation of a complex fracture network in the tight rock is crucial to improving the reservoir’s permeability. This enables trapped oil to move more freely toward the wellbore, which would otherwise be hindered by the rock’s tightness.

- Higher production rates: Regions like the Bakken and Eagle Ford have seen dramatic increases in oil production thanks to multistage fracturing. The ability to create fractures throughout the horizontal wellbore leads to much higher initial production rates compared to traditional wells.

- Improved recovery factor: While conventional wells may leave a large portion of the oil in the reservoir, multistage fracturing improves the overall recovery factor. This means more oil is recovered over the well’s lifetime, maximizing the value of the resource.

- Cost-efficiency: Although the upfront costs of multistage fracturing are higher, the increased production and extended well life typically reduce the cost per barrel of oil. This makes it an economically viable approach for tight oil formations, even in challenging price environments.

Coalbed Methane (CBM) Extraction

Coalbed methane (CBM) extraction has advanced through the use of multistage fracturing, which tackles the challenges of low permeability and water management in coal seams.

- Improved gas flow: Coal seams typically exhibit low permeability, hindering methane from easily reaching the wellbore. Multistage fracturing addresses this by creating fractures that enhance flow pathways, enabling methane to flow to the wellbore at higher rates.

- Reduced water production: Managing water produced alongside gas is a key challenge in CBM extraction. Multistage fracturing helps by forming more efficient drainage channels, lowering the volume of water produced and improving the gas-to-water ratio.

- Enhanced production efficiency: By fracturing multiple zones within the coal seam, operators can stimulate larger portions of the reservoir with fewer wells, increasing production efficiency while reducing both time and cost in CBM extraction.

- Access to previously untapped resources: Multistage fracturing allows for the extraction of methane from coal seams that were once considered uneconomical due to low permeability. This technology has unlocked new potential in CBM-rich regions that were difficult to exploit using conventional methods.

Tight Gas Development

Tight gas reservoirs, known for their extremely low permeability, rely on multistage fracturing to release natural gas trapped in dense rock formations.

- Enhanced permeability: The main challenge in tight gas reservoirs is the difficulty in gas flow due to the dense rock. Multistage fracturing improves permeability by creating multiple fractures, enabling gas to flow more easily toward the wellbore.

- Multiple fracture stages: To maximize production, tight gas formations often require several fracture stages. Multistage fracturing allows operators to stimulate different intervals within a single well, accessing gas from various layers or sections, thereby increasing overall recovery.

- Fewer wells needed: Multistage fracturing enables operators to extract gas from a larger portion of the reservoir using a single horizontal well, reducing the need for multiple wells. This lowers operational costs and minimizes environmental impact by decreasing surface disruption.

- Reduced production costs: Although extracting gas from tight formations can be expensive, multistage fracturing enhances gas flow and recovery, lowering the cost per unit of gas produced. This makes tight gas extraction more economically viable, even in lower-price markets.

Conclusion

Multistage fracturing has transformed the extraction of unconventional resources, allowing the oil and gas industry to access previously untapped reserves. By significantly enhancing production rates and recovery factors in shale gas, tight oil, coalbed methane, and tight gas formations, this technology plays a crucial role in meeting global energy demands. Its benefits—improved efficiency, lower operational costs, and reduced environmental impact—highlight its importance in the modern energy landscape.

As the industry progresses, multistage fracturing will continue to be essential for maximizing the potential of unconventional resources and promoting a sustainable energy future.