Analysis of Underbalanced Drilling in Offshore vs. Onshore Drilling

Underbalanced drilling has become increasingly valuable in both offshore and onshore settings due to its benefits in preventing formation damage, reducing drilling fluid loss, increasing production rates, etc. However, the applications, challenges, and advantages of UBD drilling differ significantly between offshore and onshore drilling environments. Here’s an in-depth analysis of how underbalanced drilling functions in these two settings and what operators should consider when implementing it.

Overview of Underbalanced Drilling

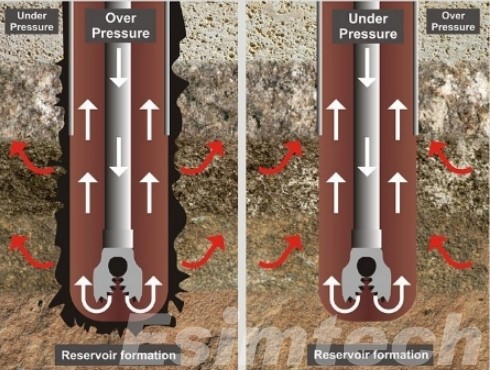

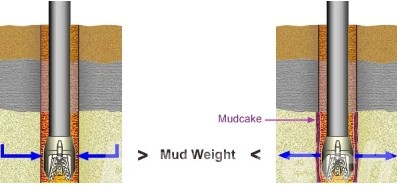

Underbalanced drilling uses controlled pressure and specialized drilling fluids to create a pressure differential between the wellbore and the formation. This approach is beneficial for formations that are highly sensitive to drilling fluids, as it minimizes invasion and damage to the reservoir. UBD drilling can improve reservoir productivity, reducing drilling time, preventing issues like differential sticking, etc. However, it also brings unique challenges, such as managing gas or fluid influx and ensuring safe handling of hydrocarbons at the surface.

Underbalanced Drilling in Onshore Drilling

How Underbalanced Drilling Onshore Works

In onshore underbalanced drilling, specialized drilling fluids (often gas-based or low-density fluids) and surface equipment are used to maintain the wellbore pressure below the formation pressure. This method often requires compressors, choke manifolds, and separators to handle the influx of formation fluids at the surface. It’s a more controlled environment compared to offshore settings, making it simpler to implement the equipment needed for UBD drilling.

Key Advantages of Underbalanced Drilling Onshore

- Reduced Formation Damage: In conventional drilling, overbalanced pressure forces drilling fluid into the formation, potentially blocking pores and reducing permeability. UBD drilling prevents this by allowing formation fluids to flow into the well, reducing invasion and preserving reservoir characteristics. This is especially valuable in tight reservoirs, where pore space is already limited.

- Enhanced Productivity: Since formation damage is minimized, the reservoir maintains its natural permeability, allowing for greater fluid flow. This can lead to improved initial production rates, especially in unconventional formations where maximizing flow is critical.

- Lower Drilling Fluid Costs: Underbalanced drilling often uses lighter drilling fluids or gases, which are typically less expensive than high-density mud systems required in conventional drilling. Reducing the volume and complexity of fluids also cuts down on the overall drilling cost.

- Reduced Risk of Differential Sticking: Underbalanced conditions minimize the likelihood of differential sticking, a common issue when the drill string adheres to the formation due to high overbalance. This can save significant time and costs associated with freeing a stuck pipe.

- Quicker Drilling Times: Underbalanced drilling often allows for faster drilling by reducing issues like fluid loss and formation pressure-induced sticking. Additionally, wells drilled with UBD drilling typically show improved wellbore stability, which can further streamline the drilling process.

Challenges of Underbalanced Drilling Onshore

- Surface Handling of Produced Fluids and Gas: Since UBD allows formation fluids and gases to enter the wellbore, handling this influx safely and effectively at the surface is critical. Specialized equipment is needed to separate, vent, or capture these fluids and gases to prevent hazards and ensure environmental compliance.

- Environmental Considerations: Underbalanced drilling operations, particularly those using air or gas drilling, may release gases that need to be managed carefully to avoid environmental impact. Vapor recovery units, flaring systems, and proper venting controls are often required to mitigate potential risks.

- Complex Equipment Requirements: UBD drilling operations typically require additional equipment such as compressors, separators, and choke manifolds. Onshore setups are more flexible compared to offshore rigs, but equipment still needs to be properly managed and maintained to ensure safety and efficiency.

- Training and Expertise: Underbalanced drilling demands a higher level of expertise and training to manage well control, handle influxes, and respond to surface pressure fluctuations. This requires operators and crews to be well-versed in UBD processes and specialized equipment operation.

Common Applications of Underbalanced Drilling Onshore

- Tight Gas and Shale Formations: Underbalanced drilling is commonly used in tight formations where traditional overbalanced drilling can cause significant formation damage. By keeping the wellbore pressure low, UBD drilling preserves the natural fractures and microfractures within these formations, facilitating greater production flow.

- Coalbed Methane (CBM): In coalbed methane reservoirs, water-sensitive formations can easily swell or clog when exposed to drilling fluids. UBD drilling prevents fluid invasion and maintains natural gas desorption pathways, enabling efficient methane extraction.

- Highly Fractured Formations: Formations with natural fractures are particularly prone to fluid loss in conventional drilling. Underbalanced drilling minimizes this risk by avoiding overbalanced pressures that can force drilling fluids into fractures, helping to maintain formation stability and fluid integrity.

- Depleted Reservoirs: In mature fields with low formation pressure, UBD drilling allows for the effective recovery of remaining hydrocarbons without excessive fluid loss. This technique is often applied in secondary and tertiary recovery efforts to optimize production.

Underbalanced Drilling in Offshore Drilling

Key Characteristics of Underbalanced Drilling Offshore

Unlike onshore drilling, offshore UBD drilling requires precise control over well pressure and surface facilities to handle formation fluids and gas safely. Offshore underbalanced drilling typically involves specialized equipment such as riser gas handling systems, managed pressure drilling (MPD) systems, and high-performance separators.

- Advanced Pressure Control: Offshore UBD drilling involves careful management of bottom-hole pressure. MPD systems and automated choke manifolds help maintain precise pressure within the well, allowing for safe drilling without inducing overbalanced pressure.

- Riser Management and Gas Handling: Offshore platforms are often equipped with riser gas handling systems to safely transport produced gas from the wellbore to the surface. These systems allow for controlled separation and handling of gas while minimizing safety risks.

- Environmental and Safety Protocols: Offshore underbalanced drilling operations adhere to strict environmental and safety protocols, as uncontrolled fluid influx could lead to hazardous situations. Blowout preventers (BOPs), emergency shutdown systems, and advanced monitoring are crucial for ensuring operational safety.

Advantages of Underbalanced Drilling Offshore

- Reduced Formation Damage: By maintaining underbalanced conditions, UBD drilling prevents drilling fluid invasion into the formation, preserving the natural permeability and productivity of offshore reservoirs. This is particularly advantageous in high-pressure and high-temperature (HPHT) reservoirs where formation damage can severely impact production.

- Enhanced Well Productivity: UBD drilling encourages a natural flow of formation fluids into the wellbore, which can result in higher production rates. In offshore fields with complex reservoirs, UBD drilling preserves reservoir characteristics, allowing operators to achieve better initial production rates and recovery.

- Extended Drilling Life: Formation damage caused by overbalanced drilling can reduce well productivity and require costly remediation. UBD drilling minimizes formation damage, potentially extending the productive life of the well and reducing the need for stimulation treatments such as acidizing or fracturing.

- Reduced Lost Circulation: Offshore reservoirs often have naturally fractured or depleted zones where conventional overbalanced drilling can result in severe mud losses. By operating underbalanced, UBD drilling reduces fluid loss and mitigates the risks associated with lost circulation, which is critical in high-cost offshore environments.

- Faster Drilling Rates: UBD drilling can enhance drilling rates by reducing frictional forces and preventing drill bit wear. This allows for quicker penetration in offshore reservoirs, reducing time and costs associated with drilling.

Challenges and Limitations of Underbalanced Drilling Offshore

While UBD drilling offers many advantages, it also presents specific challenges in offshore applications:

- Complex Equipment and Infrastructure: Offshore underbalanced drilling requires specialized equipment such as MPD systems, gas-handling risers, and high-capacity separators. Installing and maintaining this equipment on offshore platforms, especially in deepwater environments, adds complexity and cost.

- Environmental Risks: Offshore underbalanced drilling operations must be prepared to handle potential environmental impacts. Gas and fluid handling in offshore UBD involves strict environmental controls to prevent accidental releases into the ocean. In areas with tight regulatory standards, this adds complexity and operational limitations.

- High Safety Requirements: Managing high-pressure gas influx and formation fluids requires robust safety protocols. Offshore UBD demands constant monitoring, with real-time data tracking and advanced well control measures to prevent blowouts and maintain safe pressure levels.

- Costly and Logistically Complex: The costs associated with offshore UBD can be significantly higher than onshore due to the need for specialized equipment, higher operational costs, and the logistical challenges of transporting equipment to offshore platforms.

- Technical Expertise and Training: Offshore UBD drilling requires personnel with specific expertise in managed pressure drilling, gas handling, and UBD drilling equipment. This necessitates specialized training and a skilled crew to operate safely and effectively in offshore environments.

Applications of Underbalanced Drilling Offshore

- High-Pressure, High-Temperature (HPHT) Wells: Offshore UBD drilling is beneficial in HPHT environments where formation damage and lost circulation can be problematic. UBD helps maintain formation integrity and reduce the risk of fluid loss in these challenging conditions.

- Mature Offshore Fields: In depleted reservoirs, where formation pressures are low, UBD can prevent excessive mud losses and allow operators to extract remaining hydrocarbons more efficiently. This is especially valuable in offshore reservoirs where production decline requires careful management.

- Deepwater Wells: UBD drilling has applications in deepwater wells where traditional drilling may cause severe formation damage. By managing the bottom-hole pressure precisely, UBD helps in achieving better well productivity in deepwater fields with challenging reservoir characteristics.

- Naturally Fractured Reservoirs: Offshore formations with natural fractures are prone to lost circulation, which can be costly and time-consuming to manage. UBD drilling prevents drilling fluids from entering fractures, reducing the risk of fluid loss and preserving reservoir permeability.

Key Differences Between Offshore and Onshore Underbalanced Drilling

This comparison outlines the unique demands of underbalanced drilling in offshore and onshore environments, emphasizing the increased complexity, cost, and safety protocols in offshore UBD compared to the more straightforward approach often possible onshore.

| Category | Offshore Underbalanced Drilling | Onshore Underbalanced Drilling |

| Logistics and Setup | Complex logistics; equipment transported to offshore platforms or rigs | Easier access to equipment and resources; fewer transportation challenges |

| Equipment | Requires specialized equipment, including riser gas handling systems, MPD systems, and high-capacity separators | Standard underbalanced drilling equipment; generally simpler setup with fewer specialized components |

| Pressure Control | Managed with advanced MPD systems and automated chokes due to high-pressure, high-risk environments | Conventional UBD drilling pressure control; lower pressure control complexity |

| Safety Requirements | High safety demands with additional protocols for gas and fluid management | Less stringent compared to offshore; onshore sites are more accessible for emergency response |

| Environmental Concerns | Strict environmental controls to prevent offshore spills and gas emissions | Environmental risks exist, but typically have less impact than offshore |

| Operational Costs | Significantly higher due to specialized equipment and safety measures | Lower overall costs; simpler logistics and equipment reduce expenses |

| Gas Handling | Riser gas handling and flaring systems are needed to manage gas influx | Standard surface equipment typically suffices for gas management |

| Application in Reservoir Types | Common in HPHT, deepwater, and fractured reservoirs with high formation pressure | Often used in depleted reservoirs and fractured onshore formations |

| Emergency Protocols | Requires advanced emergency systems, including BOPs, emergency shutdowns, and spill containment | Easier to manage onshore with faster access to emergency response teams |

| Personnel Training | Requires highly specialized training for deepwater UBD drilling operations | Basic underbalanced drilling training; less specialization needed compared to offshore |

| Economic Viability | Higher initial investment but valuable for long-term production in challenging offshore reservoirs | Lower costs make underbalanced drilling economically viable in mature or low-pressure onshore fields |

Analysis of Simulations Used for Underbalanced Drilling in Offshore vs. Onshore Drilling

This comparison emphasizes how offshore underbalanced drilling simulations incorporate more complex scenarios and real-time monitoring to mitigate high-risk factors, whereas onshore simulations focus on efficient, cost-effective solutions for lower-pressure reservoirs.

| Category | Offshore Underbalanced Drilling Simulations | Onshore Underbalanced Drilling Simulations |

| Purpose | Handle high pressures, gas influx, and complex risks in deepwater or HPHT environments | Maintain wellbore pressure and reduce formation damage in lower-pressure reservoirs |

| Fluid Dynamics | Advanced models to manage high-pressure gas influx and fluid loss | Simpler models focused on fluid stability in low-pressure formations |

| Pressure Control | Multi-variable simulations with MPD systems to prevent kicks | Basic pressure control simulations for stabilizing low-pressure reservoirs |

| Wellbore Stability | Complex wellbore stability models with a focus on high-stakes deepwater settings | Simulations emphasizing efficient drilling |

| Equipment Planning | Simulates use of riser gas handling, MPD, and high-capacity separators | Optimizes conventional underbalanced drilling equipment like choke manifolds and separators |

| Gas and Fluid Handling | Detailed handling of gas influx and flaring operations | Basic surface gas and fluid handling simulations |

| Real-Time Monitoring | Integrates with real-time data for immediate response in high-pressure environments | Focuses on real-time adjustments for pressure management and stability |

| Safety and Environmental Scenarios | Emergency procedures, BOP deployment, and spill containment measures | Simplified safety scenarios; quick access to emergency response teams |

| Cost-Benefit Analysis | Analyzes economic viability with a focus on high-resource allocation | Focuses on cost-efficient drilling strategies for budget constraints |

In summary, underbalanced drilling offers distinct advantages and applications for both onshore and offshore environments. While onshore UBD drilling is often simpler and more economical, offshore UBD drilling brings unique challenges but also the potential for significant production benefits in complex formations. Choosing between underbalanced drilling and other drilling methods depends on reservoir conditions, environmental considerations, the balance between cost and productivity, etc.