Advances in Hydraulic Fracturing (fracking) Techniques

Hydraulic fracturing, commonly known as fracking, is a well stimulation technique in which high-pressure fluid is injected into subterranean rock formations to create fractures. These fractures allow oil and gas to flow more freely from the rock pores, increasing the extraction rate of these valuable resources. Fracking has been a game-changer in the energy sector, unlocking vast reserves of natural gas and oil that were previously uneconomical to exploit.

What is Hydraulic Fracturing (Fracking)?

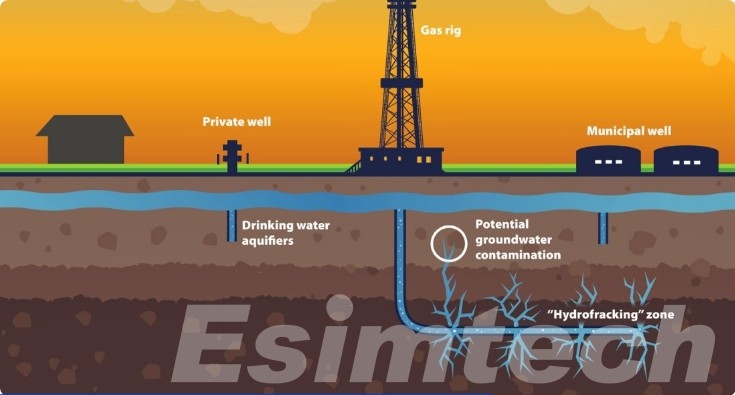

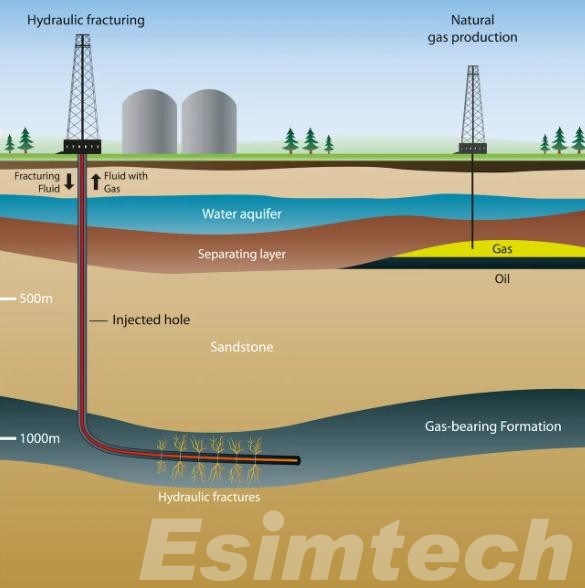

Hydraulic fracturing involves drilling a well vertically to the desired depth and then horizontally into the rock formation containing oil or gas. A high-pressure fluid, typically a mixture of water, sand, and chemicals, is pumped into the well. This fluid creates cracks in the rock formation, and the sand particles keep these fractures open, allowing hydrocarbons to flow into the wellbore and be collected at the surface. This method has significantly boosted the production of natural gas and oil, particularly in the United States, leading to energy independence and lower energy prices.

Hydraulic fracturing has been particularly successful in extracting oil and gas from shale formations, which are characterized by their low permeability. These formations contain vast amounts of hydrocarbons, but their extraction is challenging due to the tightness of the rock. Fracking has unlocked these resources, leading to a significant increase in oil and gas production, particularly in the United States. This surge in production has had several benefits:

- Energy Independence: Increased domestic production of oil and gas has reduced dependence on foreign energy imports, enhancing national energy security.

- Economic Growth: The fracking boom has created jobs, stimulated investment, and generated revenue for local and national economies.

- Lower Energy Prices: The increased supply of natural gas and oil has contributed to lower energy prices for consumers and industries.

Challenges of Traditional Fracking

Hydraulic fracturing, while instrumental in unlocking unconventional oil and gas resources, presents significant environmental, health, and economic challenges. These challenges necessitate ongoing research and development to ensure responsible and sustainable practices.

- Water Scarcity: Fracking can be highly water-intensive, requiring millions of gallons per well. This poses a substantial threat in arid regions where water resources are already limited. The intense competition for water can negatively impact agriculture, municipal drinking water supplies, and local ecosystems.

- Chemical Management: The fracturing fluid is a complex concoction of water, sand, and various undisclosed chemical additives. The lack of transparency surrounding these chemicals raises concerns about potential contamination of groundwater and soil if leaks occur during the fracking process or through improper wastewater disposal. Furthermore, potential health risks to nearby communities are a pressing issue, as certain chemicals may be linked to respiratory problems or even birth defects.

- Induced Seismicity: The high-pressure injection of fluids during fracking can, in some geologically susceptible areas, trigger earthquakes. While most of these tremors are minor, they can cause public anxiety and property damage in nearby communities.

- Methane Emissions: Leaks during fracking operations can release methane, a potent greenhouse gas, into the atmosphere. Over 80 times more effective at trapping heat than carbon dioxide in the short term, methane significantly contributes to climate change. Fugitive methane emissions from fracking sites can negate the environmental benefits of switching from coal to natural gas.

- Wastewater Management: The fracking process generates a large volume of wastewater, often a mix of fracking fluid, formation water (salty water brought up from the rock), and contaminants. Improper disposal of this wastewater can contaminate freshwater sources or pollute the environment if not treated adequately.

These challenges underscore the need for stricter regulations, advancement in technologies, and a commitment to responsible practices within the fracking industry. Addressing these issues is crucial for fracking to become a more sustainable and environmentally friendly method for extracting valuable energy resources.

Advancements in Fracking Techniques

The challenges of traditional fracking are driving significant innovation in the industry. Here’s a deeper dive into some of the most promising advancements:

Reduced Water Fracking

- Water Recycling: Fracking fluids can be treated and reused in subsequent operations, significantly reducing freshwater consumption. Advanced filtration and purification technologies are making this process more efficient and cost-effective, allowing for multiple cycles of reuse.

- Nitrogen Fracturing: This technique uses pressurized nitrogen gas instead of water to create fractures. While more expensive, it eliminates water usage concerns and reduces the risk of groundwater contamination. Nitrogen is readily available and environmentally friendly, but its use requires specialized equipment and handling procedures.

- Optimized Fluid Systems: By using specialized gelling agents and friction reducers, the industry is minimizing the total volume of water required per fracking operation. These specialized additives improve the effectiveness of the fracturing fluid at lower concentrations, reducing water usage and the associated transportation and disposal costs.

Green Fracking Fluids

- Biodegradable Additives: Researchers are developing fracturing fluids with components that break down naturally after use, minimizing the risk of long-term environmental harm. These bio-based additives can achieve similar performance characteristics to traditional chemicals but decompose rapidly after the fracturing process is complete, mitigating concerns about lingering contamination in the subsurface.

- Brine-Based Fluids: These fluids utilize naturally occurring brines (salty water) instead of fresh water. While requiring pre-treatment to remove unwanted minerals and adjust their properties, they offer a more sustainable alternative. Brine-based fluids are abundant in many oil and gas-producing regions, reducing reliance on freshwater resources.

Microseismic Monitoring

- Advanced Sensors: Deploying sophisticated downhole sensors allows for real-time monitoring of seismic activity during fracking. These sensors can detect even minor tremors, providing valuable data for optimizing injection pressures and fracture geometries. This real-time data allows operators to make adjustments during the fracking process to minimize the risk of induced earthquakes.

- Refined Fracture Modeling: Advanced computer modeling software helps predict potential seismic events based on geological formations and fluid injection volumes. By incorporating data on local geology, including fault lines and rock strength, these models can create simulations of potential fracture networks and seismic activity. This allows companies to design fracking operations that avoid sensitive geological areas and minimize the potential for seismic disruptions.

Closed-Loop Systems

- Capturing Flowback Water: These systems capture the water that returns to the surface after fracking (flowback water). This water can be treated and reused in future operations, minimizing the need for fresh water and reducing the risk of spills. Advanced separation technologies can effectively remove contaminants from flowback water, making it suitable for reuse in subsequent fracking jobs.

- Methane Emissions Reduction: Closed-loop systems capture fugitive methane emissions during fracking, preventing their release into the atmosphere and mitigating their climate impact. These systems capture vented gas from wellheads and storage tanks, allowing for its processing and utilization as a clean-burning fuel source. By minimizing fugitive emissions, closed-loop systems can significantly reduce the environmental footprint of fracking operations.

These advancements represent a significant shift towards a more sustainable and responsible fracking industry. By embracing these innovations, companies can ensure responsible resource extraction while minimizing environmental impact and addressing public concerns.

At the same time, hydraulic fracturing simulation technology continues to develop and innovate, providing a new approach to sustainable oil and gas operations.

Conclusion

Hydraulic fracturing has revolutionized the energy industry, providing access to previously untappable reserves of oil and gas. However, traditional fracking methods have faced significant environmental and economic challenges. The recent advancements in fracking techniques are addressing these issues, making the process more efficient, cost-effective, and environmentally friendly. As technology continues to evolve, the future of hydraulic fracturing looks promising, offering a balanced approach to meeting energy demands while minimizing environmental impact.