Advancements in Offshore Well Intervention Technologies in Oil and Gas Recovery

The oil and gas industry has always been at the forefront of technological innovation, and offshore well intervention is no exception. As global energy demands continue to rise, the need for efficient, cost-effective, and environmentally sustainable methods of oil and gas recovery has become paramount. Offshore well intervention technologies have evolved significantly over the years, enabling operators to maximize production, extend the life of wells, and reduce operational risks.

Evolution of Offshore Well Intervention Technologies

Offshore well intervention has progressed significantly since its inception. In the beginning, interventions were mostly reactive, addressing concerns like equipment malfunctions or decreased output rates. These activities were frequently expensive, time-consuming, and presented substantial safety concerns to people. Traditional approaches depended mainly on rig-based interventions, which necessitated enormous, costly equipment and lengthy downtime.

Over time, the sector turned toward more proactive and preventative measures. Light-well intervention vessels and riderless systems have emerged, lowering costs and increasing efficiency. The introduction of subsea well intervention technologies further transformed the industry by allowing operators to reach and maintain wells in deeper waters. Today, the emphasis is on integrating sophisticated technologies like robotics, automation, and real-time data analytics to improve health intervention procedures.

Current Advancements in Offshore Well Intervention

The latest advancements in offshore well intervention technologies are transforming the way operators approach oil and gas recovery. These innovations are not only improving operational efficiency but also enhancing safety and reducing environmental impact. Below are some of the key advancements shaping the industry:

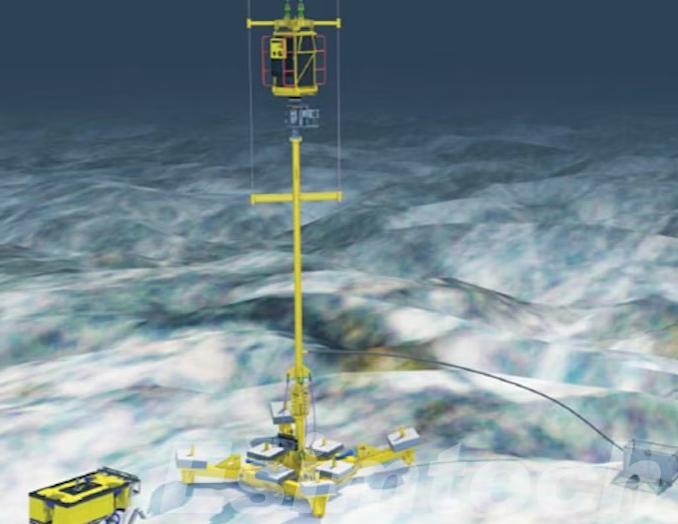

Robotic and Autonomous Systems

Robotic and autonomous systems are transforming offshore well intervention by removing the need for human intervention in dangerous locations. Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) can currently handle difficult tasks, including checking subsea equipment, cleaning wellbores, and even making small repairs. These devices have advanced sensors and cameras that provide real-time data to surface operators. Robotic systems improve safety and save operational downtime by limiting human exposure to potentially hazardous settings.

Downhole Tools and Sensors

The development of sophisticated downhole instruments and sensors has allowed operators to collect important data on well conditions without incurring costly interventions. Advanced sensors can track characteristics like pressure, temperature, and flow rates in real-time, enabling more precise decision-making. Downhole tools, like as logging instruments and perforation devices, have also improved in precision and reliability. These innovations enable operators to swiftly detect problems and apply targeted solutions, resulting in improved well performance.

Coiled Tubing and Snubbing Technologies

Coiled tubing and snubbing technology have advanced significantly, making offshore well interventions faster and more successful. Coiled tubing—continuous tubing deployed into the well for purposes like as well cleaning, pressure testing, and fluid injection—has been strengthened with more durable, corrosion-resistant materials. This invention improves the system’s capacity to withstand harsh offshore conditions. Similarly, snubbing, which involves moving tubular in a well while under pressure, has become safer and more efficient with the development of more powerful and dependable snubbing devices. These innovations expedite operations, allowing operators to respond swiftly and effectively, especially in high-pressure situations.

Wireline Technology

Wireline technology, a staple of offshore well intervention, has also evolved tremendously. Modern wireline systems now have better data transmission capabilities, allowing real-time data from downhole instruments to be communicated to the surface. This quick information transfer assists in making timely decisions to maximize performance. Furthermore, new wireline systems are built to tolerate severe temperatures and pressures, making them more useful in difficult offshore wells. With these advancements, wireline technology remains an important instrument for logging, perforating, and monitoring well conditions, hence contributing to better overall management of offshore oil and gas reservoirs.

Role of Well Intervention Simulators in Oil and Gas Recovery

Well intervention simulators have emerged as a game-changing tool in the oil and gas industry, offering a virtual environment to plan, test, and optimize intervention operations before they are executed in the field. These advanced systems play a critical role in enhancing the efficiency, safety, and success rates of offshore well interventions, particularly in complex and high-risk environments. By integrating real-time data, advanced modeling, and immersive training capabilities, well intervention simulators are transforming how operators approach oil and gas recovery.

Main Types of Well Intervention Simulators

- Hydraulic Simulators: These model the behavior of wellbore fluids, helping operators predict pressure changes, fluid flow rates, and potential issues like fluid losses or kicks. They’re commonly used in coiled tubing and snubbing operations.

- Mechanical Simulators: These focus on tool deployment, pipe movement, and equipment performance, assessing the mechanical integrity of downhole tools and how they will perform under different conditions.

- Real-Time Data Integration Simulators: These combine real-time data from sensors and surface equipment to create a dynamic well model. This allows operators to adjust interventions as they unfold, improving decision-making and minimizing risks.

- VR and AR Simulators: Offering immersive training environments, these simulators allow personnel to practice complex procedures safely, especially for high-risk operations like deepwater or subsea interventions.

Role of Well Intervention Simulators

Well intervention simulators are playing an increasingly important role in oil and gas recovery. These advanced software systems allow operators to model and simulate intervention scenarios before executing them in the field. By replicating real-world conditions, simulators help identify potential challenges and optimize intervention strategies, reducing the risk of costly mistakes.

Simulators also serve as valuable training tools for personnel, enabling them to practice complex procedures in a controlled environment. This is particularly important for offshore operations, where the margin for error is slim. Additionally, simulators can integrate real-time data from downhole tools and sensors, providing a comprehensive view of well conditions and improving decision-making.

Conclusion

To conclude, technological advancements in offshore well intervention are leading to substantial improvements in oil and gas recovery. Innovations such as robotic systems, advanced downhole tools, coiled tubing, and wireline technologies are enhancing safety, efficiency, and sustainability in operations. Well intervention simulators also contribute by improving planning, training, and decision-making processes. As the industry progresses, these technologies will be essential in addressing global energy needs while reducing environmental impact.