A Comprehensive Guide to Hydraulic Fracturing

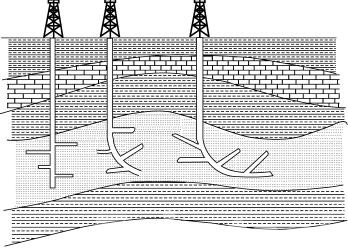

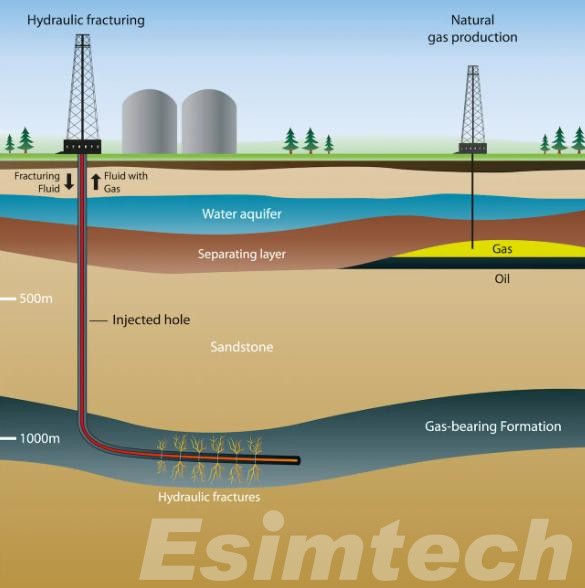

Hydraulic fracturing, commonly known as fracking, has become a significant technique in the extraction of oil and natural gas from deep within the Earth’s crust. This process involves injecting high-pressure fluid into underground rock formations to create fractures, allowing the release of valuable resources. In this comprehensive guide, we will delve into the process of hydraulic fracturing, explore the benefits it brings, assess its environmental impact, and examine how simulation technology can enhance this extraction method.

What’s the Process of Hydraulic Fracturing?

Hydraulic fracturing, commonly known as fracking, is a process used to extract oil and natural gas from deep underground. Here’s a general overview of the hydraulic fracturing process:

Site Preparation

- Environmental Impact Assessment: Before initiating drilling, a comprehensive environmental impact assessment is conducted to evaluate potential effects on local ecosystems, water resources, and communities.

- Regulatory Compliance: Strict adherence to regulatory requirements is paramount. Permits are obtained, and operators work closely with regulatory agencies to ensure compliance with environmental and safety standards.

- Infrastructure Development: In addition to the well pad, infrastructure such as access roads and storage facilities is developed. Measures are implemented to control erosion and minimize disturbance to the surrounding environment.

Horizontal Drilling

- Technological Advancements: The drilling process involves cutting-edge technologies, such as Measurement While Drilling (MWD) and Logging While Drilling (LWD), providing real-time data on subsurface conditions.

- Directional Drilling Techniques: Advanced directional drilling techniques are employed to navigate the drill bit through complex geological formations with precision. This allows for increased reservoir contact and higher extraction efficiency.

Well Completion

- Reservoir Evaluation: Before completion, reservoir evaluation tools are used to assess the properties of the rock formation, including permeability and porosity, aiding in the design of an effective completion strategy.

- Zonal Isolation: To prevent fluid migration between different geological zones, zonal isolation techniques, such as cementing, are applied during well completion.

Fracturing Fluid Injection

- Tailored Fluid Formulations: Fracturing fluids are customized based on the geological characteristics of the formation. The composition may include water, proppants, and chemical additives to optimize fracturing efficiency.

- Pressure Control: High-pressure pumps exert precise control over the injection process, ensuring that fractures propagate uniformly through the target formation.

Proppant Injection

- Proppant Transport and Placement: Innovations in proppant transport and placement technologies enhance the distribution of proppants within fractures, maximizing their effectiveness in keeping fractures open.

- Research and Development: Ongoing research explores new proppant materials and coatings, aiming to improve performance and minimize environmental impact.

Fluid Flowback

- Flowback Management Systems: Advanced flowback management systems are employed to capture, treat, and recycle fluids. This minimizes freshwater usage, reduces waste generation, and addresses concerns about fluid disposal.

- Water Treatment Technologies: Technologies like membrane filtration and chemical precipitation are utilized to treat flowback water, ensuring that it meets environmental standards before disposal or reuse.

Production

- Optimized Production Techniques: Downhole monitoring and control systems optimize production rates and ensure the sustainable extraction of hydrocarbons.

- Integrated Data Analytics: Big data analytics and machine learning algorithms are increasingly used to analyze vast datasets from well operations, aiding in reservoir management and production optimization.

Community Engagement and Transparency

- Stakeholder Involvement: Operators engage with local communities, addressing concerns and providing information about the fracking process. Open communication fosters transparency and builds trust.

- Education Initiatives: Educational programs are often implemented to inform the public about the technical aspects, safety measures, and regulatory frameworks governing hydraulic fracturing.

Throughout the entire process, a commitment to safety, environmental stewardship, and continuous improvement is crucial. Ongoing research and collaboration within the industry contribute to advancements in technology and practices, aiming to make hydraulic fracturing more efficient, sustainable, and environmentally responsible.

What Can People Benefit from Hydraulic Fracturing?

Hydraulic fracturing, while controversial, offers several potential benefits, although it’s crucial to acknowledge the accompanying concerns and weigh them carefully. Here’s a breakdown of the main advantages:

Economic Benefits

- Increased energy production: Fracking has led to a significant increase in the production of natural gas and oil, particularly in the United States. This can lower energy prices for consumers, benefit industries that rely on these resources, and potentially enhance energy security by reducing dependence on foreign imports.

- Job creation: The fracking industry creates jobs in well-drilling, maintenance, transportation, and related fields. This can lead to economic growth and increased tax revenue in areas where fracking activity is concentrated.

- Government revenue: Fracking activity generates taxes and royalties for governments, which can be used to fund infrastructure, education, and other public services.

Environmental Benefits (relative, compared to other fossil fuels)

- Cleaner Burning Fuel: Natural gas burns more cleanly than coal, emitting lower levels of carbon dioxide and other pollutants during electricity generation. This has the potential to significantly reduce air pollution and contribute to efforts in mitigating climate change.

- Reduced Reliance on Coal: The increased availability of natural gas, facilitated by fracking, can lead to a transition away from coal-fired power plants. This shift not only improves air quality but also helps in reducing overall greenhouse gas emissions.

Other Potential Benefits

- Energy Independence: A rise in domestic production of oil and gas, facilitated by fracking, can decrease reliance on foreign energy sources. This potential boost in energy independence may enhance national security and contribute to geopolitical stability.

- Advancements in Technology: The fracking industry drives technological innovations that extend beyond the energy sector. Improved drilling techniques and materials developed in this context can have positive spillover effects, benefiting various industries and enhancing overall technological capabilities.

What’s the Potential Drawbacks of Hydraulic Fracturing?

It’s crucial, however, to acknowledge that these benefits should be considered alongside potential drawbacks associated with hydraulic fracturing:

Environmental Concerns

- Water contamination: The large volumes of water used in fracking, along with the chemicals present in the fracking fluid, can pose a risk of contaminating groundwater and surface water. Leaks or spills can occur at various stages of the process, and chemicals can migrate through fractures into aquifers. This can endanger drinking water supplies and harm aquatic ecosystems.

- Air pollution: Fracking operations can generate air pollution from emissions of volatile organic compounds (VOCs), methane, and other pollutants. This can contribute to smog, respiratory problems, and climate change.

- Induced earthquakes: The high pressure used in fracking has been linked to an increase in the frequency and intensity of earthquakes in some areas. These earthquakes can damage infrastructure and pose a safety risk to people and property.

- Wastewater disposal: Fracking generates large volumes of wastewater containing chemicals and brine. Improper disposal of this wastewater can contaminate water sources and harm wildlife.

Social and Economic Concerns

- Health impacts: Residents living near fracking sites may be exposed to air and water pollution, raising concerns about potential health effects such as respiratory problems and cancer.

- Community disruption: Fracking operations can disrupt local communities, leading to noise, traffic, and light pollution. They can also raise concerns about property values and quality of life.

- Impact on local water resources: The large volumes of water used in fracking can put a strain on local water resources, especially in arid regions. This can lead to competition for water between fracking operations and other users, such as agriculture and communities.

- Transparency and regulation: Concerns exist about the transparency of the fracking industry and the effectiveness of regulations in protecting the environment and public health.

It’s important to note that the severity of these drawbacks can vary depending on several factors, including the specific location, regulations in place, and the practices employed by the fracking company. Additionally, research on the long-term impacts of fracking is ongoing, and some of the risks are still being evaluated.

Can Simulation Technology Enhance Hydraulic Fracturing?

Simulation technology stands as a transformative force in enhancing hydraulic fracturing processes. By enabling engineers to model and optimize well designs, fluid dynamics, and stress conditions, simulations contribute to more efficient and informed decision-making. Proppant placement and real-time monitoring further refine the fracturing process, maximizing productivity. Simulation tools also play a crucial role in predicting and assessing environmental impacts, addressing concerns such as water and air contamination.

Additionally, these technologies offer training platforms for skill development and contribute to cost reduction through scenario optimization. Continuous innovation in simulation drives advancements, making it an integral component for responsible and efficient hydraulic fracturing practices.

Chengdu Esimtech presents the ESIM-FFA2 fracturing and acidizing simulation training system, a cutting-edge solution catering to the training needs of oilfield companies. Combining petroleum engineering, computer technology, and virtual reality, it covers modules on fracturing devices, design, construction, process, acidizing fracturing, and accident analysis. Tailored for training personnel, workers, and technicians, the system ensures mastery of device operations, understanding of fracturing and acidizing processes, and proficiency in handling common fracturing accidents through practical training and testing.

If you have any interests, please feel free to contact us, our team is standing by for you!